Bag closing sewing machines are used in various industries, including agriculture, food processing, and construction. In agriculture, for instance, they are ideal for sealing bags of grains, seeds, and fertilizers. In the food industry, these machines are crucial for packaging flour, rice, sugar, and other bulk food items. Their ability to handle different bag types and materials makes them an indispensable tool across multiple sectors.

What is a Twin Needle?

To get started with chain stitching, one needs basic sewing tools fabric, appropriate thread, and a sewing machine or needle for hand stitching. Selecting the right type of thread is crucial, as the thread should complement the fabric’s texture and weight. The proper tension settings on the sewing machine are essential for achieving a flawless chain stitch and preventing issues like thread breakage or puckering.

In addition to garment making, the single needle lock stitch has applications in quilting. Quilters often rely on this stitch to piece together layers of fabric and batting, providing the necessary durability and integrity. Home decor projects like pillow covers, curtains, and table linens also benefit from this stitch for a clean and professional finish.

For crafters who enjoy working with leather or canvas, a heavy-duty machine can make all the difference. With the right needle and adjustments, these machines can sew through several layers of thick materials effortlessly, providing a clean finish and professional result. Moreover, heavy-duty sewing machines often come with attachments and accessories that further expand their capabilities, such as walking feet for even feeding of layers and heavy-duty needles for robust sewing tasks.

Needle feed sewing machines are widely used across different sectors of the textile industry. In the garment manufacturing sector, they are essential for sewing complex patterns, fortifying seams, and working with layered fabrics. This capability makes them particularly valuable for producing high-quality clothing items, including suits, dresses, and outerwear.

4. Cutting Blade For machines that seal bags at the same time they are cutting, the cutting blade plays a critical role. It ensures that each bag is of uniform size and cuts through the material cleanly. A sharp and well-maintained blade contributes to the overall efficiency and prevents material wastage.

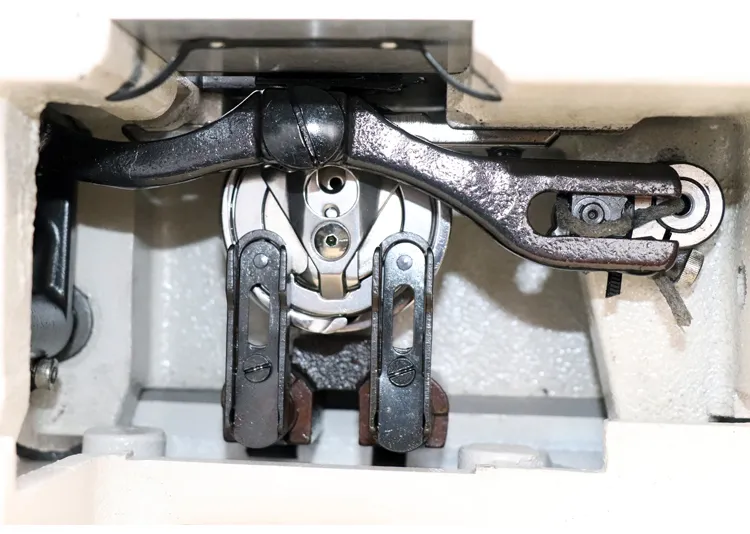

bag closer machine parts

The Essential Guide to Upholstery Sewing Tables

The impact of automotive sewing machines on the automotive industry extends beyond mere efficiency. The quality of upholstery plays a crucial role in consumer satisfaction, influencing not only the aesthetic appeal of a vehicle but also its perceived value. Well-made seats and interior components contribute significantly to comfort and luxury, factors that are increasingly important to consumers in a competitive market.

A traditional hand-powered leather sewing machine is designed specifically for sewing leather, which is known for its durability and thickness. These machines typically feature robust metal construction, ensuring longevity and stability during use. The most notable component is the hand crank, which allows the user to control the sewing speed and stitch precision. This manual control is highly valued as it enables craftsmen to manage delicate curves and intricate designs that automated machines might struggle with.

Key Features to Look For

1. Adjustable Stitch Length and Width This allows for customization based on fabric type and project requirements. Look for machines with a wide range of settings.

Next, bring the needle up through the fabric slightly to the right of your first stitch. Make another loop and bring the needle back down through the fabric, catching the loop to create a second chain stitch. Continue alternating between making chain stitches to the left and right of your original stitches to create a double thread chain stitch.

double thread chain stitch

Bulk bag sewing machines are specialized equipment designed to automate the sewing process for bulk bags. Unlike traditional sewing machines, which may not handle the size and weight of bulk bag materials efficiently, these machines are equipped with features tailored for heavy-duty fabric. With powerful motors and robust sewing mechanisms, bulk bag sewing machines can handle thick, layered fabrics such as polypropylene, which is resistant to wear and tear.

Heavy-Duty Sewing Machines: Since these machines cater to domestic users, their accessories and replacement parts are relatively easy to find. Many sewing stores and online platforms offer components compatible with popular heavy-duty machine models.

5. After-Sales Support Companies that offer comprehensive after-sales support, including installation, training, and maintenance services, may charge more for their machines. However, this support can be invaluable for ensuring optimal performance and longevity of the equipment.

- Industrial Equipment Suppliers If you’re looking for a heavy-duty chain stitch sewing machine for commercial use, consider reaching out to suppliers that specialize in industrial sewing equipment. These suppliers often carry a broader range of high-performance machines.